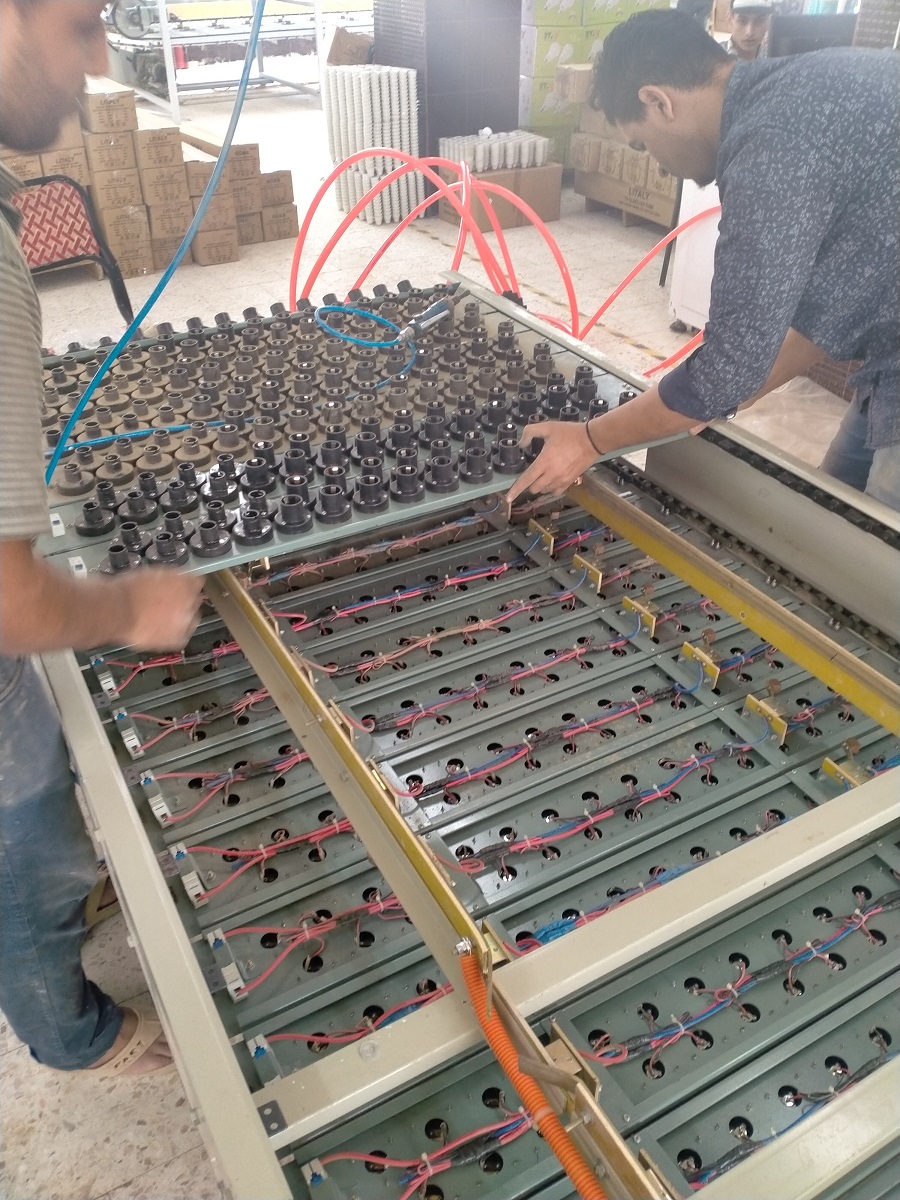

LED Bulb Testing Line

The technology of Light Emitting Diode (LED) lighting is considered one of the most prominent technologies that have flooded the market and brought about a revolution in the field of lighting. LED bulbs provide energy-efficient lighting and have a long lifespan compared to traditional technologies such as fluorescent bulbs and incandescent lamps. In response to the growing proliferation of this modern technology, LED bulb manufacturers must ensure the quality of the products they offer. This is where the importance of LED bulb testing lines comes into play. LED bulb testing lines allow for precise and efficient testing and monitoring of LED bulbs. The main purpose of these lines is to verify the performance and quality of LED bulbs and ensure they meet specified specifications and standards. Below is an overview of the importance and components of LED bulb testing lines

Product Features

- 1. Electrical Performance Testing: This test involves measurements such as voltage, current, power, power factor, and frequency for the LED bulb. It ensures that the bulb operates correctly according to electrical standards

- 2. Illuminance Testing: This test involves measurements such as luminous intensity, color temperature, and spectral analysis. It assesses the quality of illumination and its compatibility with various application requirements

- 3. Bulb Durability Testing: This test involves repeated endurance tests for the LED bulb to verify its strength and longevity

- 4. Safety Testing: This includes tests to ensure the bulb's safety concerning electrical currents, heat, and regulations

- 5. Efficiency Testing: LED bulb testing lines must also measure the bulb's efficiency and energy consumption to ensure energy savings.

- 6. Advanced Testing: These tests also include special tests tailored to the specific requirements and applications of the bulb

Services Categories

-

Development of an LED bulb assembly line 0

-

Development of CNC Winder Machines 6

-

Development of Swing Gaming Control Panels 0

-

Control Systems Development 1

-

Assembly and Commissioning of Imported Production Lines and Machinery 3

-

Maintenance Contracts, Technical Support, and Engineering Consultations 0

-

Installation of Surveillance Systems 0

-

Installation of Time and Attendance Systems 0

-

Installation of Telephone Systems 0

-

Server Installation 0

-

Installation of Audio Systems 0

Related Services